How Electrochemical Gas Sensors Work and Key Parameters for Gas Detection

What is an electrochemical gas sensor?

The electrochemical gas sensor is a commonly used gas sensor that can detect various gases, including:

- Inorganic toxic gases: oxygen, carbon monoxide, carbon dioxide, ammonia, hydrogen cyanide, and hydrogen sulfide

- Combustible gases: acrylonitrile, acetylene, ammonia, carbon monoxide, ethylbenzene, chloroethane, chloromethane, epichlorohydrin, propylene oxide, hydrogen cyanide, propane, propylene, hydrogen sulfide

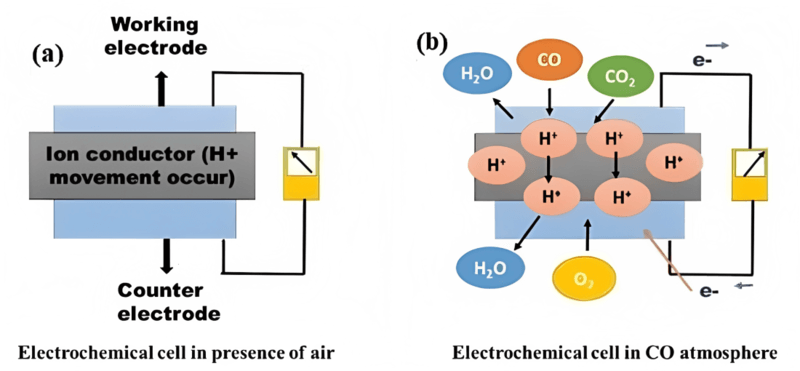

The electrochemical gas sensor is based on the electrochemical properties of the target substance and converts the chemical quantity of the target substance into an electrical quantity for sensing and detection. It works by reacting with the measured gas and generating an electric signal proportional to the gas concentration.

Most electrochemical gas sensors are current sensors that generate a linearly proportional electric current to the gas concentration.

Figure: Electrochemical cell in the presence of air and CO atmosphere

Components of an Electrochemical Gas Sensor

Figure: Components of an Electrochemical Gas Sensor

- Permeable Membrane (also known as Hydrophobic Membrane): The permeable membrane is used to cover the sensing (catalytic) electrode, and in some cases, it is used to control the molecular weight of the gas reaching the electrode surface. The selection of electrode material is crucial.

- Electrode: The selection of electrode material is crucial. The electrode material should be a catalytic material capable of undergoing a semi-electrolysis reaction for an extended period of time, typically made of precious metals such as platinum or gold, which react effectively with gas molecules after catalysis.

- Electrolyte: The electrolyte must be capable of undergoing an electrolysis reaction, effectively transferring ionic charge to the electrodes. Sometimes a scrubber filter is installed in front of the sensor to filter out unwanted gases.

- Filter: The selection of filters is limited, with each filter having varying degrees of efficiency. The most commonly used filtering material is activated carbon.

Working principle of electrochemical gas sensor

An electrochemical gas sensor works by reacting with the gas being measured and producing an electrical signal proportional to the gas concentration.

A typical electrochemical sensor consists of a sensing electrode and a counter electrode, separated by a thin electrolyte layer. Using tiny capillary openings and hydrophobic barrier layers, an appropriate amount of gas can react with the sensing electrode to form a sufficient electrical signal while preventing electrolyte leakage. The gas concentration is determined by measuring the current proportional to the concentration of the gas being measured.

To improve the performance of the sensor, a reference electrode is introduced to maintain a fixed voltage value on the sensing electrode.

Gas molecules react with the sensing electrode while measuring the counter electrode, and the measurement results are usually directly related to the gas concentration.

Figure: The Measurement Method of Electrochemical Gas Sensor

Characteristics of Electrochemical Gas Sensors

Advantages

- Not contaminated by other gases. The presence of other environmental gases will not shorten the life of the sensor.

- Good repeatability and accuracy. Once calibrated to a known concentration, the sensor will provide repeatable readings of the target gas.

- Linear output, low power consumption, and good resolution.

Figure: The Wiring Diagram of Electrochemical Gas Sensor and Arduino, ESP32, and Raspberry Pi

Disadvantages:

- Unable to perform a qualitative analysis of unknown gases.

- The sensor has a certain lifespan.

- Over-range high concentrations can cause failure.

- Special attention must be paid to storage.

The main parameters of an electrochemical gas sensor?

- Detection type and lifespan: The lifespan of an electrochemical sensor varies depending on the gas it detects. The lifespan of an electrochemical sensor for ordinary gases is usually 2-3 years, such as carbon monoxide or hydrogen sulfide sensors. However, some special gases, such as hydrogen fluoride gas sensors, have a lifespan of only 12-18 months.

Figure: Gravity: Factory Calibrated Electrochemical CO Sensor

- Range: The highest gas concentration that can ensure the parameters listed in the sensor specification.

Different gas sensors have their own range, as low as 1ppm and as high as 100%vol. A 1ppm range sensor is used to measure highly toxic gases, while a 100%vol range sensor is used to measure high-concentration oxygen.

- Sensitivity: The change in the output current or voltage of the sensor when the concentration of the measured gas changes by one unit. Sensitivity units such as nA/ppm or uA/ppm, etc.

- Response Time: The time it takes for the sensor signal to rise from zero to a certain percentage of the ventilation equilibrium point is called the response time. When oxygen or toxic gases exceed the range harmful to the human body, personnel must evacuate the environment. The shorter the evacuation time, the more time is left for evacuees. Therefore, the shorter the response time of the sensor, the better.

- Humidity Range: The humidity range in which the sensor can work normally.

- Storage Temperature: The temperature that is most beneficial to the life of the sensor when it is not in use. The most suitable storage temperature for an EC sensor is 0°C ~ 20°C.

Applications

- Environmental Air Quality Monitoring

The decline in air quality caused by industrialization poses a threat to the quality of life, with the main air pollutants being nitrogen oxides, sulfur oxides, hydrogen sulfide, and some volatile organic compounds. Electrochemical gas sensors are now becoming an essential tool for monitoring and controlling pollutants that affect air quality. They provide a cheaper alternative for widespread air monitoring compared to traditional and more expensive air quality monitoring instruments based on infrared spectroscopy and gas chromatography.

- Detection of Explosive and Toxic Gases

In hazardous areas within the manufacturing and chemical industries, explosion prevention is receiving increasing attention due to the presence of toxic and flammable gases. Monitoring these hazardous areas helps to achieve a safer working environment. Government and industry regulations, such as COSHH and OSHA, require workers to limit exposure to toxic gases and fumes. This has led to an increase in the use of electrochemical gas sensors, which offer better sensitivity and selectivity for a wide range of toxic gases.

- Oxygen Monitoring in the Medical Field

Electrochemical oxygen sensors are used in many brands and models of medical respirators and ventilators for respiratory therapy, life support systems, and emergency medicine.

When critically ill patients may not be able to get enough oxygen from the surrounding air due to respiratory problems, ventilators provide a mixture of medical-grade oxygen-rich air from pressurized tanks and the surrounding air.

The percentage of oxygen required depends on the severity of the patient's condition, so measuring the concentration and flow of oxygen is critical to the patient's health.

The small size, ease of implementation, and simple operation of electrochemical sensors make them ideal detection and monitoring devices in the healthcare field.

Figure: Electrochemical Sensors for Healthcare

- Food Quality Control

The use of electrochemical sensors in food industry applications is increasing. Carbon dioxide and ethanol are used in the food and beverage industry, so continuous gas detection is needed to prevent people from ingesting toxic or harmful gases.

Other applications that require gas detection include steam processes, inert gases for packaging, carbonated gases, toxic gases for sterilization, and ammonia for refrigeration.

Figure: Electrochemical Sensors for Food quality control

Conclusion

Electrochemical gas sensors represent a burgeoning class of sensor products that boast a trifecta of desirable traits: compact dimensions, heightened sensitivity, and effortless assembly. This makes them a highly valuable asset in a diverse range of fields, including but not limited to agriculture, environmental monitoring, and healthcare. These sensors are capable of detecting an array of gases, encompassing both inorganic toxic gases and combustible gases. They possess commendable reproducibility and accuracy, linear output, low power consumption, and excellent resolution, among other advantages.

However, it must be noted that electrochemical sensors are incapable of qualitatively analyzing unknown gases, and they possess a finite lifespan. Exposure to concentrations exceeding their operational parameters may result in sensor failure, necessitating careful storage and handling.

As sensor technology continues to advance, electrochemical sensors will undoubtedly proliferate and find their way into practical applications, particularly in the realm of IoT construction where they can demonstrate their full worth.